Add RelGen to Charge Your Liftgate.

Eliminate Stuck Trucks For Good.

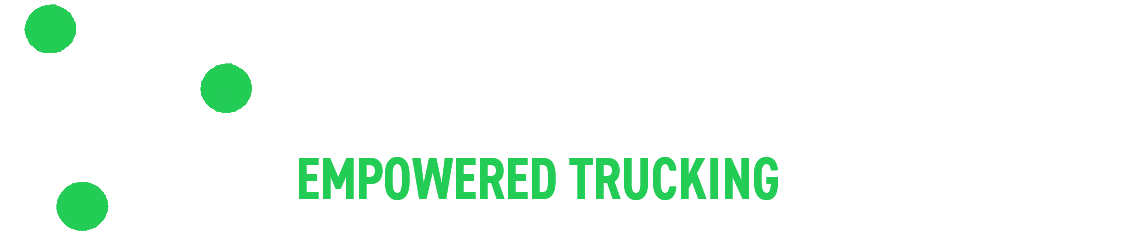

Are your liftgates letting you down? 80% of liftgate failures are due to low voltage in the liftgate batteries. For many fleets this leads to dead trucks as well as liftgates. RelGen solves low voltage problems by providing 200 amps of additional dedicated charging for your liftgate batteries.

RelGen’s design is more efficient at delivering charge to liftgate batteries than other charging platforms. RelGen design overcomes voltage loss that plagues engine mounted alternators because the charging unit is installed next to the auxiliary batteries, minimizing or eliminating voltage loss.

RelGen makes power from the rotation of the drive shaft behind the transmission. At low speeds, “the transmission effect” allows RelGen to make power with lower percentage of the engine’s available torque. At higher vehicle speeds the driveshaft spins faster than the engine crank shaft giving RelGen up to a 30% higher RPM which creates more power in less time. This allows RelGen to generate power at a faster rate while the truck is in motion.

RelGen also uses a high efficiency 200 amp 12 volt alternator that is 15% more efficient than factory alternators helping to reduce your fuel consumption while keeping your equipment on the road. Fleet owners can save as much as $3000/truck per year in fuel alone.

RelGen replenishes batteries faster than any other solution on the market, keeping your batteries fully charged. Full batteries gives you the confidence to eliminate engine idling during deliveries which saves fuel, reduces maintenance repairs and lowers CO2 emissions. Improve your uptime and profitability with RelGen’s dedicated 200 amps of charging capacity.

Add RelGen for Sleeper Cabs.

Eliminate Idling For Good.

Maximize your investment in your most important asset – your drivers!

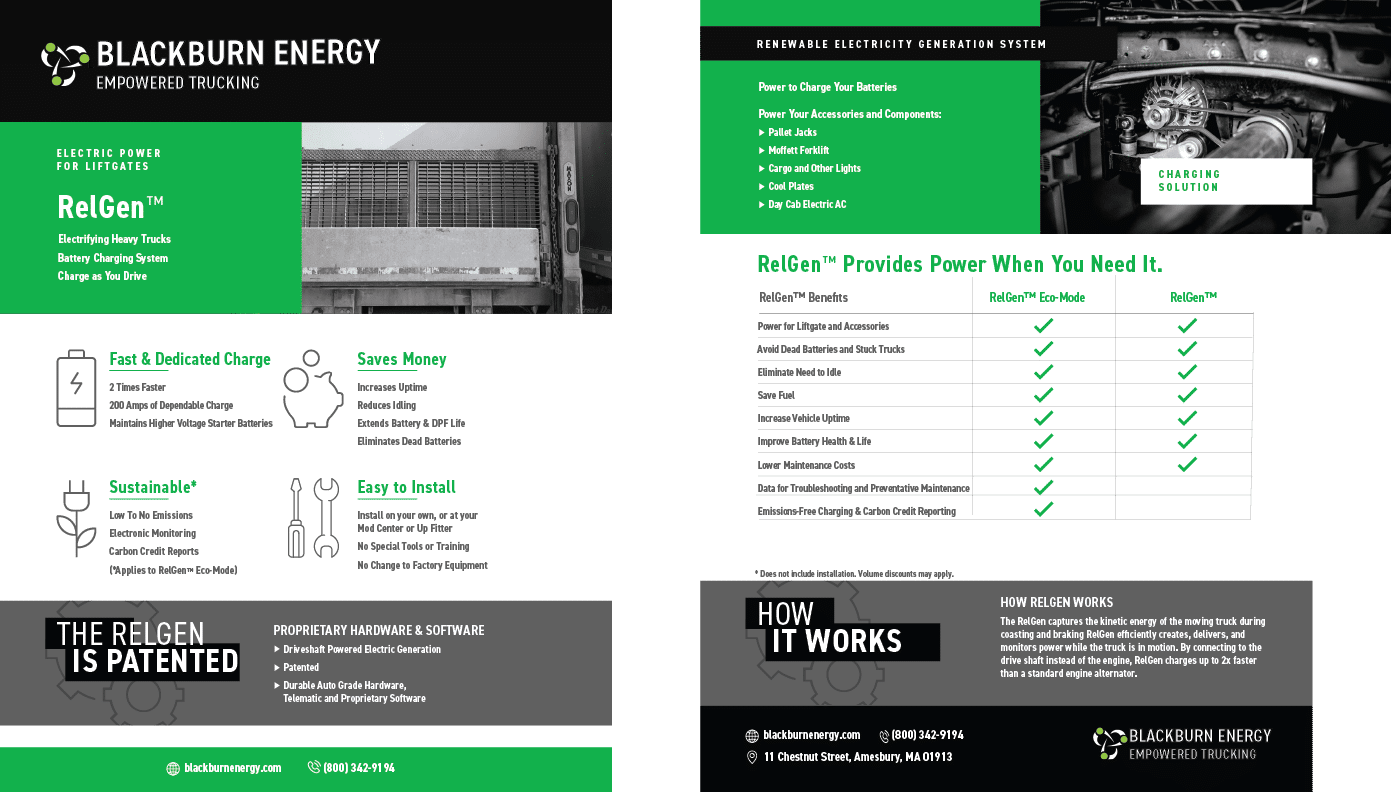

Drivers need a reliable source of electric power for living essentials – electrified air conditioners, phones, crock pots and microwaves, sleep apnea machines and refrigerators. But all too often they lack the power to operate this equipment and are forced to idle their engines for long periods of time. This costs the fleet in fuel and maintenance repairs. In addition, a low quality living environment for the driver contributes to high turnover among fleets.

RelGen can provide all the power needed for the modern driver to live and the best fleets to maximize their investment in their equipment and drivers.

For instance, for an electric APU to keep a driver cool and comfortable for a full 8 hours, it needs its batteries charged to 100%. Even an upgraded engine alternator is not able to deliver a full charge to these batteries. RelGen™ guarantees a fast and full charge that maximizes the value of your electric APU.

In typical electric APU configurations, voltage drop occurs across long power cables connecting the engine alternator to the APU batteries. RelGen charges more efficiently because it is installed next to the auxiliary batteries, minimizing this power loss. The system is located behind the transmission where it collects energy from the driveshaft which spins faster than the engine alternator. This allows RelGen to generate power at a faster rate while the truck is in motion. The batteries are charged up to 100%, eliminating the need to idle for power at night. Fleet owners can save as much as $6000/truck per year in fuel alone.

RelGen’s innovative charging solution allows an electric APU to function at peak performance. It keeps the driver cool and comfortable, powers appliances, and improves their living conditions without the need to idle. Happier drivers help fleet owners improve driver retention.

Combining RelGen™ with an electric APU can prevent the release of 17 tons of CO2 emissions per truck annually. With many states adopting strict idling laws, RelGen™ is a cost-effective solution to avoid fines.

RelGen 48V.

Solving The Charging Gap.

Blackburn Energy’s 48V Charging System is a vehicle electrification platform.

Transitioning to higher voltage architectures creates opportunities to reduce emissions and optimize costs through weight reductions and higher fuel efficiency. The increase in available power enables the electrification of auxiliary engine components including safety systems, cooling systems, braking, steering, and air-conditioning.

One of the main industry challenges with transitioning to 48V is the need to maintain a 12V electrical system for components that are not ready for the transition. Maintaining a multi-volt system is challenging and adds complexity to the vehicle.

The RelGen 48V electrical system is isolated from the truck’s 12V system. They function in parallel with none of the challenges and complexity inherent to a multi-volt system. Having the two separate voltage systems allows for the transition of mechanical engine components to 48V components while still using 12V components that have not yet been developed for 48V.

Blackburn keeps the cost to transition at a minimum Blackburn eliminates the need for more expensive batteries by using four dependable lead-acid batteries in series to create our 48V storage system.

© 2024 Blackburn Energy All Rights Reserved.